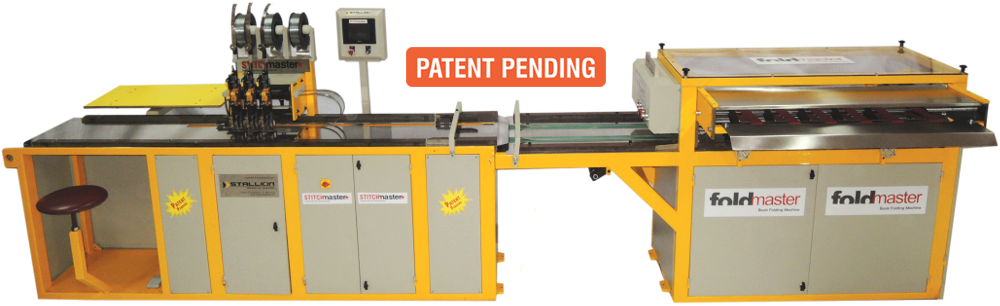

World's first & only Technology for programmable wire Stitching with less heads… Proudly invented by Stallion

World's first & only Technology for programmable wire Stitching with less heads… Proudly invented by Stallion

HIGHLIGHTS:

High Speed

High Speed

Less Heads – multiple Stitches

Less Heads – multiple Stitches

Upto 24 stitches per book possible

Upto 24 stitches per book possible

Exact distance between two stitches

Exact distance between two stitches

Minimum distance between two stitches

Minimum distance between two stitches

Minimum make ready time

Minimum make ready time

“V” at margins well maintaineds

“V” at margins well maintaineds

No skilled labour required

No skilled labour required

Suitable for hard cover books

Suitable for hard cover books

Cost Effective & Economic

Cost Effective & Economic

High Speed

High Speed Less Heads – multiple Stitches

Less Heads – multiple Stitches Upto 24 stitches per book possible

Upto 24 stitches per book possible Exact distance between two stitches

Exact distance between two stitches Minimum distance between two stitches

Minimum distance between two stitches Minimum make ready time

Minimum make ready time “V” at margins well maintaineds

“V” at margins well maintaineds No skilled labour required

No skilled labour required Suitable for hard cover books

Suitable for hard cover books  Cost Effective & Economic

Cost Effective & Economic

HOW IT WORKS:

| 1. | Gathered papers (book blocks) are individually fed into the machine. |

| 2. | They are gripped and moved to the correct position(S) to be stitched and then transported on. |

| 3. | The length of book, number of stitches and the distance between stitches is programmed into the machine. These can be saved if needed in the future with a maximum of 20 saved settings available. |

| 4. | Stitchmaster will then make a stitch at the exact location as per this program. Up to 24 stitches per book can be achieved in this way. |

| 5. | Once stitched as required the book is then transported onward where if required the Foldmaster will use its multiple roller sets to give a tight and exact high quality centre fold. |

| 6. | If you couple the Foldmaster with our Online SQUARE then this device will grip the folded book and shape the folded edge perfectly in 90 degrees to give a sqaure edged fold (even with heavy stock covers) |

| 7. | All of these machines are modular in nature so can be in unison or individually as required. |

TECHNICAL SPECIFICATIONS:

| Speed | : | Upto 30 sections / minute |

| Book Length | : | max. 1040mm - min. 400mm |

| Book Width | : | max. 430mm - min. 280mm (Open Book) |

| Book Thickness | : | STITCHmaster max. 8mm - min. 2 sheets (Open Book) FOLDmaster & SQUARE max. 16mm - min. 4mm (Folded Book) |

| Power | : | 5.5 HP(4.1 kw), 415V AC, 50 HZ |

| Air Supply | : | Compressor required, Air pressure 6kg/cm3 |

| Dimensions | : | 4800 x 2300 x 1500 mm (Length x Width x Height) L-Shaped |